How to use the cluster carbon oxygen gun reasonably to improve the benefit of electric furnace steelmaking

Release time:

2024-04-09

In China, more than 70% of electric arc furnaces use furnace door carbon and oxygen guns. It can be seen that furnace door carbon and oxygen guns are important to electric arc furnace smelting. The reason is that the price of natural gas is high, the consumption is large, and the effect after use is not obvious. Therefore, the furnace door carbon and oxygen guns play a major role. In order to increase the stirring effect of furnace door carbon and oxygen guns, many enterprises have continuously increased the flow rate of furnace door carbon and oxygen guns, what's more, the flow rate of the carbon and oxygen gun in the furnace door reaches 5000 Nm3/h, while the flow rate and pressure are constantly increasing, and the outlet pressure is as high as 16kg.

In China, more than 70% of electric arc furnaces use furnace door carbon and oxygen guns. It can be seen that furnace door carbon and oxygen guns are important to electric arc furnace smelting. The reason is that the price of natural gas is high, the consumption is large, and the effect after use is not obvious. Therefore, the furnace door carbon and oxygen guns play a major role. In order to increase the stirring effect of furnace door carbon and oxygen guns, many enterprises have continuously increased the flow rate of furnace door carbon and oxygen guns, what's more, the flow rate of the carbon and oxygen gun in the furnace door reaches 5000 Nm3/h, while the flow rate and pressure are constantly increasing, and the outlet pressure is as high as 16kg.

I want to analyze from a scientific point of view, the difference between the furnace door carbon and oxygen gun, the furnace wall telescopic carbon and oxygen gun, and the cluster carbon and oxygen gun:

1) Furnace door carbon and oxygen gun, single-hole supersonic oxygen gun, theoretical range 20 times throat diameter, 5000 Nm3/h, about 730mm, intense carbon and oxygen reaction causes a large amount of oxygen waste and steel material loss, carbon powder sometimes does not fully react although slag flows out together.

2) The furnace wall telescopic carbon and oxygen gun is not different from the furnace door carbon and oxygen gun in essence. It is a single-hole supersonic oxygen gun. The theoretical range is only 20 times of the throat diameter, 5000 Nm3/h, and about 730mm. Because the furnace wall telescopic oxygen gun is far away from the furnace door, the loss of steel material is better than that of the furnace door carbon and oxygen gun. The severe carbon and oxygen reaction also has low oxygen utilization rate because of limited range, steel material loss and other hidden dangers.

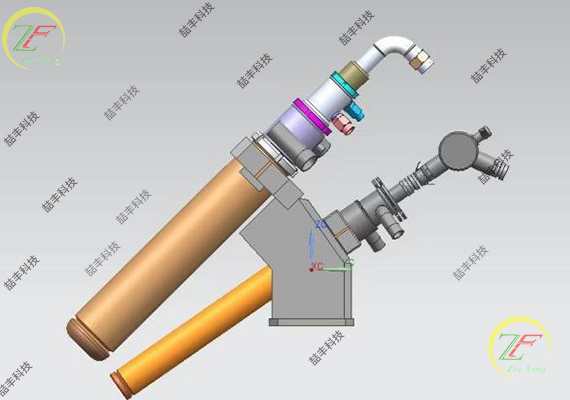

3) The cluster carbon and oxygen gun can reach Mach 2.2, 2000 Nm3/h and theoretical range of 1.7m at a pressure of 16kg, which is 3.5 times the range of the same flow rate furnace door carbon and oxygen gun or retractable furnace wall carbon and oxygen gun. Because it is far away from the furnace door and the widely used carbon gun is arranged at the lower part of the oxygen gun, the utilization rate of carbon powder is improved, and the utilization rate of oxygen and the yield of steel material are improved.

It is recommended to use the furnace wall carbon and oxygen gun as the main furnace door carbon and oxygen gun or telescopic carbon and oxygen gun as the auxiliary production process to improve economic efficiency. To investigate the effect of using carbon and oxygen guns on the furnace wall, it is recommended that a steel enterprise in Yutian, Hebei, a steel enterprise in Fengrun, Tangshan, a steel enterprise in Huainan, Anhui, a steel enterprise in Fogang, Guangdong, a steel enterprise in Guigang, Guangxi, a steel enterprise in Fuan, and a steel enterprise in Hanzhong, Shaanxi.

Keyword: