Why develop oxygen burner?

During the melting period of the electric furnace, under the action of the strong arc of the 3 (or single electrode) electrodes, the furnace charge under the electrode is rapidly melted, and the scrap steel in the furnace is pierced into 3 holes. With the process of heat transfer from the inside to the outside in the cross-well zone, the melting area expands continuously from the cross-well zone to the outside, forming a gradual melting process of the charge. Thus, three cold zones must be formed between the electrodes near the furnace wall, thereby prolonging the melting time. Especially in the use of ultra-high power (high power) electric arc furnace, the impact of the cold zone is more prominent. In addition, in order to solve the matching problem of electric arc furnace and continuous casting, it is necessary to increase the input power of electric arc furnace and shorten the smelting time. Fusing technology has been widely used all over the world, and has achieved the effect of reducing power consumption by 30 ~ 70kwh/t, smelting time can be shortened by 5~20min, and cost reduction by 5~20 yuan/t. The fuel used is generally natural gas.

What is a water-cooled furnace door carbon and oxygen gun

Water-cooled furnace door carbon and oxygen gun refers to the furnace door oxygen blowing equipment cooled by oxygen blowing device with water. Oxygen blowing and carbon powder spraying can be integrated or separated. When integrated, the center hole of the head of the oxygen lance is a carbon powder spraying hole, and the lower oxygen spraying hole can be a single hole or two holes. The hole and the axis of the oxygen lance are 45 ° downward, and the included angle between the axes of the two holes is 30 °. The oxygen nozzle adopts a double-hole supersonic nozzle design to strengthen the role of splashing and stirring. For the design range of nozzle Mach number, the outlet velocity range Ma = 1.6~2.2 and the oxygen flow rate (standard state) Q = 1800~4000 m3/h are generally selected according to the oxygen supply conditions of the factory. When oxygen blowing and carbon spraying are separated, carbon powder is generally blown from the furnace wall through the furnace wall carbon gun. The water-cooled oxygen lance is a specially designed water-cooled oxygen lance matched by three-layer steel pipes (outer diameter φ122~219mm) and inlaid with a copper nozzle.

What is a self-consuming furnace door oxygen blowing equipment?

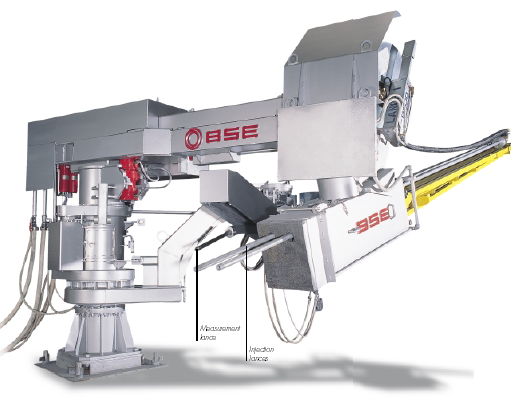

Self-consuming furnace door carbon and oxygen gun refers to a kind of consumption equipment in which oxygen blowing tube and carbon powder nozzle are gradually melted into molten steel with the smelting process. The diameter of the consumable pipe is generally much smaller than that of the water-cooled oxygen lance, so the oxygen blowing and carbon spraying are more flexible. The self-consuming furnace door carbon and oxygen gun is represented by the German BSE multi-functional combination gun.

The multi-function combination gun LM2 (as shown in the figure) of BSE Company of Germany is a combination equipment with the functions of oxygen gun, carbon gun manipulator and lateral temperature sampling manipulator. The complete LM2 manipulator consists of a solid steel structure and is mounted on a cylinder together with two rotating hands. The upper rotating hand support is the driving device of oxygen gun and carbon gun, and the lower rotating hand supports a chassis for installing temperature sampler. Sampling and temperature measurement are carried out under the conditions of continuous power supply, uninterrupted oxygen blowing and carbon blowing.

Xinjiang Bayi Iron and Steel Co., Ltd. 70t ultra-high power DC arc furnace adopts the gun manipulator developed by BSE company in Germany. Daye special steel 70t ultra-high power electric arc furnace adopts multi-function combination gun LM2.

What does the enhanced oxygen process equipment mainly refer?

Generally speaking, the main oxygen blowing methods of electric furnaces include: furnace door oxygen blowing and furnace wall oxygen blowing. Correspondingly, the main strengthening oxygen process equipment includes: furnace door water-cooled carbon oxygen gun, furnace door self-consuming oxygen gun, furnace wall oxygen burner, furnace wall cluster jet oxygen gun.

Why does the oxygen burner not use air?

In industry, the oxygen required for combustion is generally provided by air. However, since the nitrogen in the air is also heated to the temperature in the furnace, it takes away a lot of heat when it leaves the furnace, reducing the combustion efficiency and losing the energy used to melt the charge.Using pure oxygen instead of air has two major advantages:

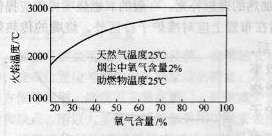

(1) The flame temperature is increased.As shown in the figure, as the amount of oxygen in the combustion air increases, the flame temperature also increases. Under pure oxygen conditions, the flame temperature can reach 2700-2800℃.

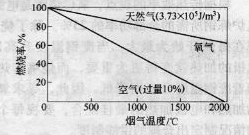

(2) The combustion rate is improved.As the flue gas temperature rises, the air combustion rate decreases rapidly, and in the case of pure oxygen, the combustion rate decreases very little. Therefore, for the flue gas temperature of 1600℃, the combustion rate of pure oxygen exceeds 70%, while the air combustion rate is only about 20% as shown in the figure.

Relationship between flame temperature and oxygen content

The relationship between combustion rate and flue gas stability