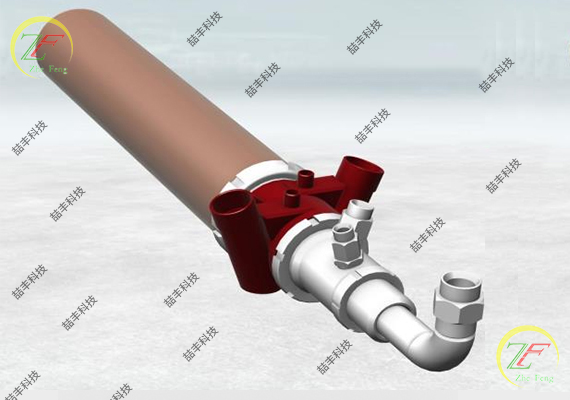

Cluster oxygen lance comes out

Release time:

2024-04-09

In recent years, electric arc furnace steelmaking technology has developed rapidly at home and abroad. Around the expansion of production capacity, reduce consumption indicators, reduce production costs, many steel-making auxiliary technology came into being. Among them, the oxygen cluster jet technology plays a very important role in improving the rhythm of electric furnace smelting and reducing production costs.

In recent years, electric arc furnace steelmaking technology has developed rapidly at home and abroad. Around the expansion of production capacity, reduce consumption indicators, reduce production costs, many steel-making auxiliary technology came into being. Among them, the oxygen cluster jet technology plays a very important role in improving the rhythm of electric furnace smelting and reducing production costs.

The input chemical energy of electric arc furnace steelmaking is an effective method to reduce power consumption and speed up smelting rhythm. Blowing oxygen to the molten pool is a direct means of inputting chemical energy. At the same time, blowing oxygen to the molten pool has many other favorable factors, such as accelerating the decarburization rate, reacting with the injected carbon powder to form foam slag, stirring the molten pool, etc. The common method of blowing oxygen in the electric furnace is ordinary supersonic jet, which uses ordinary oxygen lance to obtain supersonic oxygen jet at high pressure (5-15 atmospheric pressure) through the nozzle, so as to achieve special metallurgical effect by using its high-speed dynamic performance. The main disadvantages of the traditional supersonic oxygen lance are: short blowing distance and relative dispersion, so that the impact of the oxygen jet on the molten pool is small, the molten steel is easy to form splash, the effective use rate of oxygen in the furnace is low, and the power saving effect is poor.

In order to overcome this deficiency of ordinary supersonic oxygen lance, Praxair Company of the United States has developed the condensed jet technology, which can maintain its original speed, diameter, gas concentration and injection impact force within the injection distance 70 times of the nozzle diameter than the traditional supersonic jet. The impact force at 0.254m of the traditional oxygen lance is equivalent to that at 1.37mm of the condensed jet. The depth of impact on the molten pool is more than twice as high, the expansion and attenuation of the air flow should be small, reducing the splashing of the molten pool and the sticking of the nozzle. Germany and the United Kingdom and China with oxygen research units have also developed the technology. The world's more famous cluster oxygen lance suppliers include Praxair, KT, PTI, ACI, RCB, More, BSE, NKK, etc.

Keyword:

Previous article