Principle of cluster jet

Release time:

2024-04-09

The principle of the cluster jet oxygen lance is to add a burner around the Laval nozzle, so that the oxygen jet of the Laval nozzle is surrounded by high temperature and low density medium, reducing the influence of various airflow in the electric furnace on the central oxygen jet, thus slowing down the attenuation of the velocity of the oxygen jet, maintaining the initial diameter and velocity of the oxygen jet in a long distance, and providing a long-distance supersonic polymerization jet to the molten bath [8].

The principle of the cluster jet oxygen lance is to add a burner around the Laval nozzle, so that the oxygen jet of the Laval nozzle is surrounded by high temperature and low density medium, reducing the influence of various airflow in the electric furnace on the central oxygen jet, thus slowing down the attenuation of the velocity of the oxygen jet, maintaining the initial diameter and velocity of the oxygen jet in a long distance, and providing a long-distance supersonic polymerization jet to the molten bath [8].

The cluster jet oxygen lance is designed by applying the principle of gas mechanics. The main point is that the main oxygen flow in the center of the nozzle points to the molten pool. The high kinetic energy and blowing speed are not enough to keep the jet in a bundle state over a long distance. In order to achieve the purpose of keeping the jet in a bundle state, another medium must be used to guide the oxygen, that is, the gas flow is added, so that the gas flow acts as an envelope to the main oxygen flow. The low-speed gas flow provides more kinetic energy than the static gas, which is conducive to the high-speed blowing of the oxygen jet, this allows the primary oxygen flow to maintain its exit diameter and velocity over a longer distance.

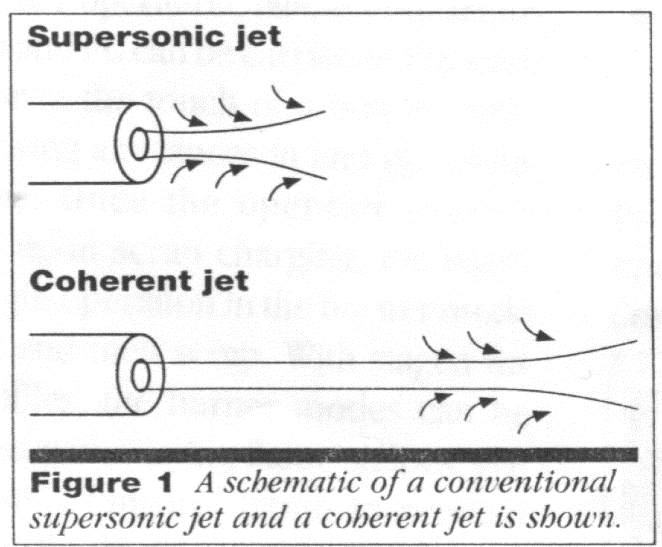

The core of the cluster jet technology is the special nozzle. When the nozzle installed on the furnace wall blows oxygen into the molten pool of the electric arc furnace in a cluster manner, the cluster oxygen flow maintains its original speed and diameter over a long distance than the ordinary supersonic jet, as shown in the figure below.

Comparison of Cluster Jet and Ordinary Supersonic Jet

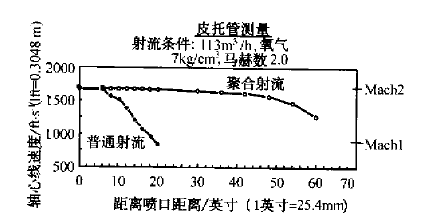

Axis Velocity Curve of Cluster Jet and Traditional Jet

As can be seen from the above figure, the speed of the ordinary jet has decayed to the speed of sound at 20 inches from the outlet, while the speed of the cluster jet at 60 inches is still supersonic at about 1400 feet per second. The attenuation of the coherent jet stream is obviously lower than that of the ordinary supersonic jet, the length of the core area can be more than 70 times of the nozzle outlet diameter, and the diffusion rate of the jet is also significantly reduced. At the same time, the core length of the polymerization jet, the diffusion and decay speed of the jet can be controlled by adjusting the process parameters of the oxygen lance nozzle.

The cluster jet has the following characteristics:

(1) The original velocity, diameter, gas concentration and injection impact force can be maintained within the injection distance of more than 70 times the nozzle diameter;

(2) The impact force at 0.254m of the ordinary supersonic oxygen lance is equivalent to that at 1.37m of the cluster jet; the depth of impact on the molten pool is more than twice as high, the expansion and attenuation of the air flow is small, and the splashing of the molten pool and the sticking of the nozzle are reduced;

(3) Compared with ordinary supersonic injection, the amount of ambient air brought in is less than 10%, and NO emission is reduced;

(4) The speed of jet diffusion and decay is also significantly reduced.

(5) The depth of the impact liquid molten pool is about 80% deeper than that of the ordinary jet. The water model test also shows that the depth of the cluster jet into the molten pool is more than 80% larger than that of the traditional injection.

(6) The length of the core area of the cluster jet, the diffusion and attenuation of the jet and its pressure can be controlled.

(7) The bath mixing time is similar to the bottom blowing mixing time.

(8) Splashing is greatly reduced.

Keyword: